Assisted Mining

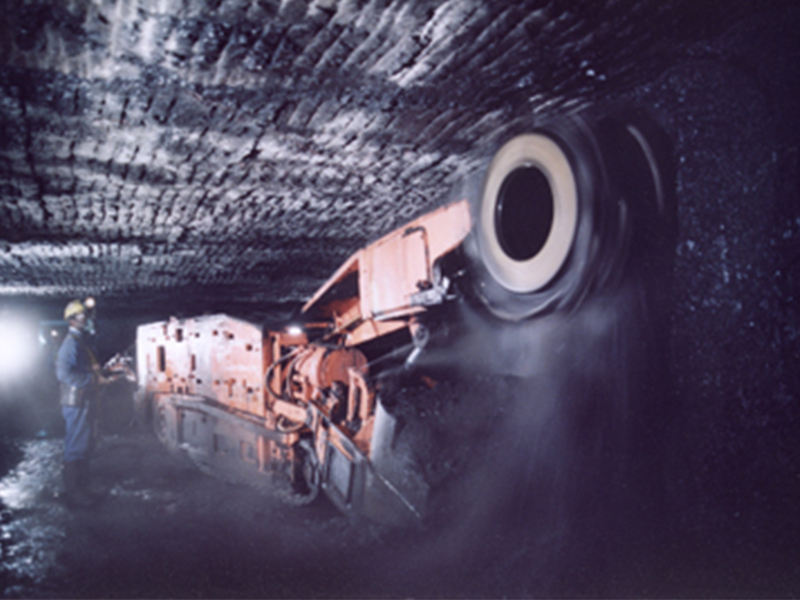

NREC applied robotic sensors to the development of semi-automated continuous mining machines and other underground mining equipment.

Sensors mounted on the mining equipment can accurately measure the machine's position, orientation and motion. These sensors will assist operators standing at a safe distance to precisely control the machine.

Application

The U.S. is a world leader in coal production, but profits are continually squeezed. Utility deregulation presses prices down while smaller and shorter seams limit productivity while increasing the costs of mining. Poor visibility underground limits efficiency, as do requisite safety precautions, which nevertheless fail to prevent accidents, injuries and fatalities.

NREC, in collaboration with partners NASA and then Joy Mining Machinery (now Joy Global), developed robotic systems for semi-automating continuous miners and other equipment used for underground mining.

Capabilities

NREC mounted sensors on a Joy continuous miner to accurately measure the machine’s position, orientation, and motion. These sensors assist operators standing at a safe distance to precisely control the machine. Increases in operating precision heighten productivity in underground coal mining and decrease the health and safety hazards to mining workers.

System Description

NREC team developed two systems to improve equipment positioning:

Sump Depth: This system measures the sump depth of a continuous mining machine without the use of external infrastructure. It is useful for matching the volume of cut coal with the capacity of the haulage vehicles and for increasing productivity via faster sequencing of mining operations.

Heading: A global heading measurement system uses a laser reference to help the continuous mining machine cut a straight entry. This system helps eliminate trim cuts, reduces extra roof bolts, and increases productivity via accelerated sequencing.

Performance

The system can measure sump depth with no more error than two percent (2%) of distance traveled, and track heading within one centimeter lateral offset and 1/3 degree heading error.

Photos